1997 Year of foundation

Frank Klotz and Georg Gangloff found the “Gangloff und Klotz Schmiedekunst und Schlosserei” and start working with 3 employees.

1998 Change of company name

The company at the former Zinkhütte Stolberg site is renamed to its current name “Klotz & Gangloff GmbH”.

2000 Mechanical Engineering

With Jens Gangloff, the company expands its portfolio to include mechanical engineering. The company size has grown to 10 employees.

2001 Relocation

In order to keep up with the constant growth, larger production halls are necessary. The move to the newly built, own hall in Eschweiler, to the current location, follows.

2003 Industrial assembly

The company expands its portfolio with the third pillar: industrial assembly. The number of employees has grown to 15.

2006 Managing partner

Jens Gangloff joins the management board.

2008 CAD Construction

Initially only for its own needs, the company builds up its own CAD design department.

2010 Change in management

Georg Gangloff leaves his position as managing partner. The company now employs 23 people.

2012 Solar plant

In order to produce most of the required electricity in-house, the entire roof area of the hall is equipped with its own solar system.

2016 3D Scanner

We are one of the first companies in our industry to invest in state-of-the-art laser technology: a 3D scanner for fast and precise indoor and outdoor measurements.

2017 CAD/CAM Design and Construction

The company expands its portfolio to include the fourth pillar: CAD/CAM design. The company name also adapts to the changes and becomes Klotz & Gangloff GmbH “Maschinenbau und Stahlbau”. With now 63 employees, the company grows steadily.

2018 Hall celebration

For the 20th anniversary, a big hall party was celebrated with customers and friends. Fun fact: 1,000L of beer were served that weekend.

2019 Expansion design and construction

Extension of the construction building and expansion of the team.

2020 Realignment with focus on project business

By focusing on projects, we were able to meet the requirements of our pharmaceutical customer West as well as other customers.

2020 Warehouse & production area expanded

The Wagner Hall now serves as a storage and production area for, among other things, the assembly of projects.

2021 Largest charging station installer in DE

So far, we have installed around 10,000 charging stations throughout Germany as part of the overall project!

2023 Intermediate management level

An interim management level was successfully established to strengthen efficiency and structure. Intermediate management received targeted training and additional skills. By strengthening the intermediate management level, we took an important step to make the organizational process more effective and to better respond to customer needs.

2023 Keyence 3D measurement technology

Keyence is revolutionizing 3D measurement technology with an accuracy of ±0.003mm and a generous measuring range of up to R = 7m. The technology not only allows users to precisely measure objects, but also enables them to redesign components based on captured 3D data.

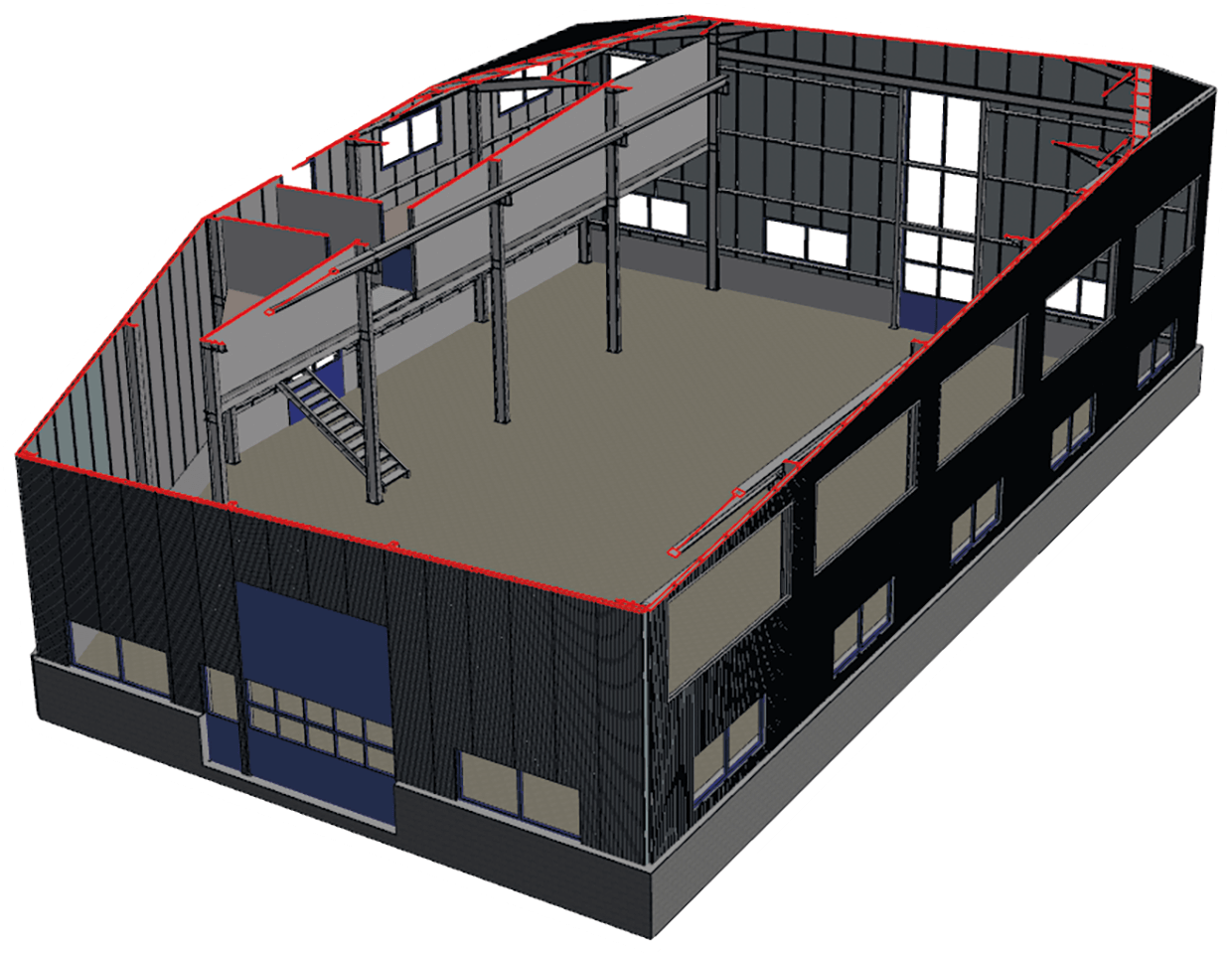

2024 Expand hall space

Our PV system is being expanded from 40 kWp to 280 kWp in order to achieve self-sufficiency of over 60 %.

2024 Intermediate management level

We are expanding our hall space by building a new assembly hall with a generous 600 m² of floor space. This expansion not only provides additional space for assembly activities, but also includes the creation of our own training academy. With this we are laying the foundation for the comprehensive training and development of skilled workers in our company.